BROMBAL ITALY - PART DUE

Brombal Italy – Part Due | September, 2016

Following another 4-course meal, the second part of our tour began with a trip to

Zanatta Glass. Italian safety regulations are a bit more lax than those in the USA, so without a pair of safety goggles, steel toed boots or hard hat in sight, we stayed well within the designated yellow lines while enormous sheets of glass flew overhead. Zanatta’s 430,550 sq ft facility processes, tempers, laminates and assembles insulated glass units up to 10.5’ x 24.5’ as well as producing glass for the automotive and naval industries. Their sophisticated machinery, inspections and testing processes ensure a high-quality final product without warping or defects (ie. very clear glass).

Hydraulic work tables are raised vertically to receive glass panes to avoid stressing and breaking the glass.

Large glass sheets are scored by machines into the required sizes minimizing waste. All glass offcuts are also recycled.

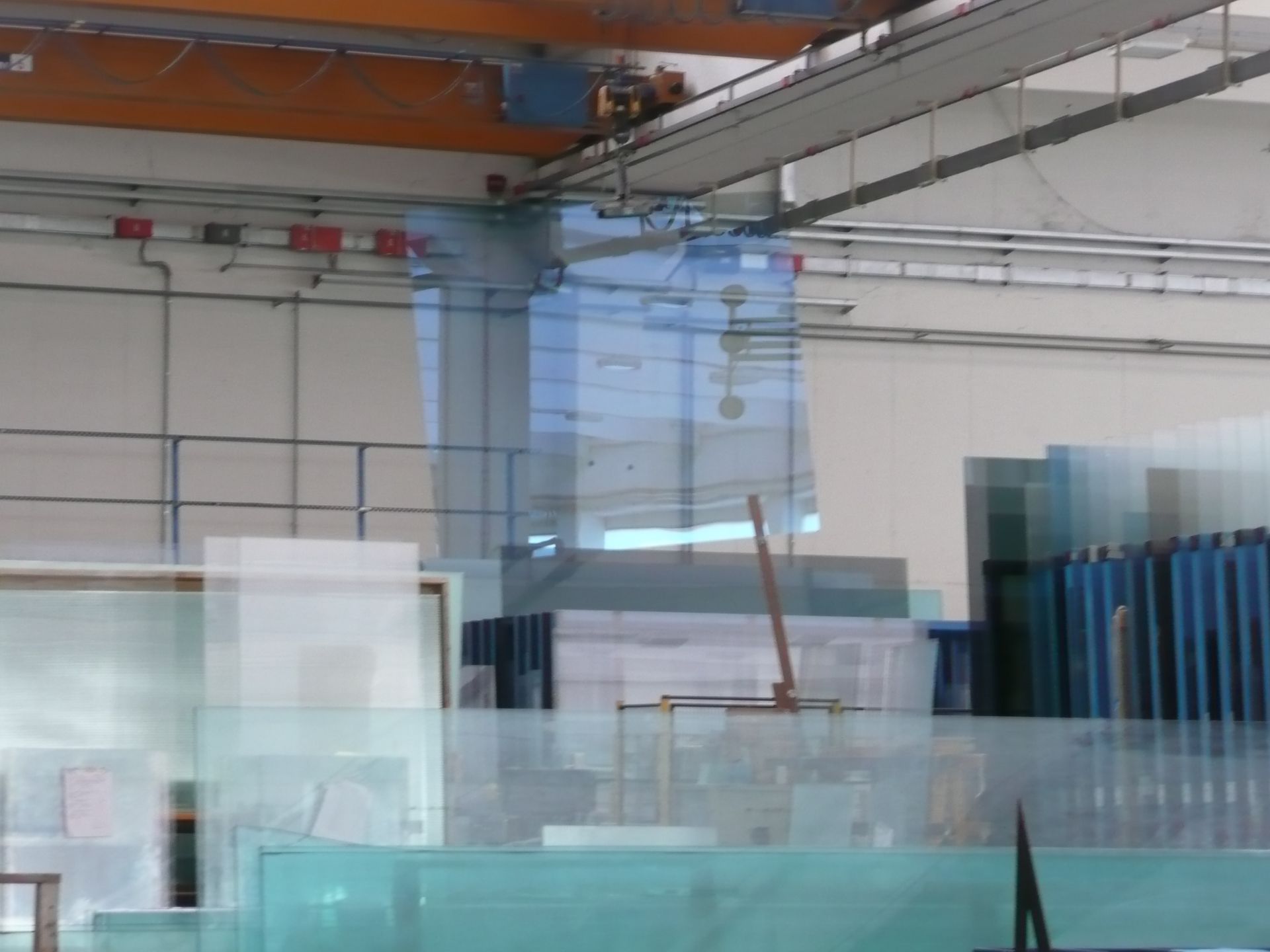

Insulated glazing spacer bar.

Our final stop was the recently expanded Serramenti Brombal. Here we were able to see the final assembly of the Secco Profiles into custom window and door units by skilled craftsmen and meet their impressive drafting and engineering staff. There are very few machines in the Brombal factory and we were able to see employees assembling, welding, sanding and finishing each window by hand. This level of quality and attention to detail does come at a premium and Brombal has recently begun to produce some lower cost windows, to be more competitive with US manufacturers, by incorporating welded hinges and aluminum glazing beads. While they continue to recommend their higher quality product, these modifications, which are standard on many other steel windows, represent significant savings.

welded hinges

Brombal’s adjustable hinges allow for minute adjustments during installation for smooth operation as well as over the life of the window to accommodate changes such as settlement and material expansion and contraction.

Hand finishing of connections between the window frame and mullions make welded joints invisible to the eye.

Corten Steel patina applied by hand

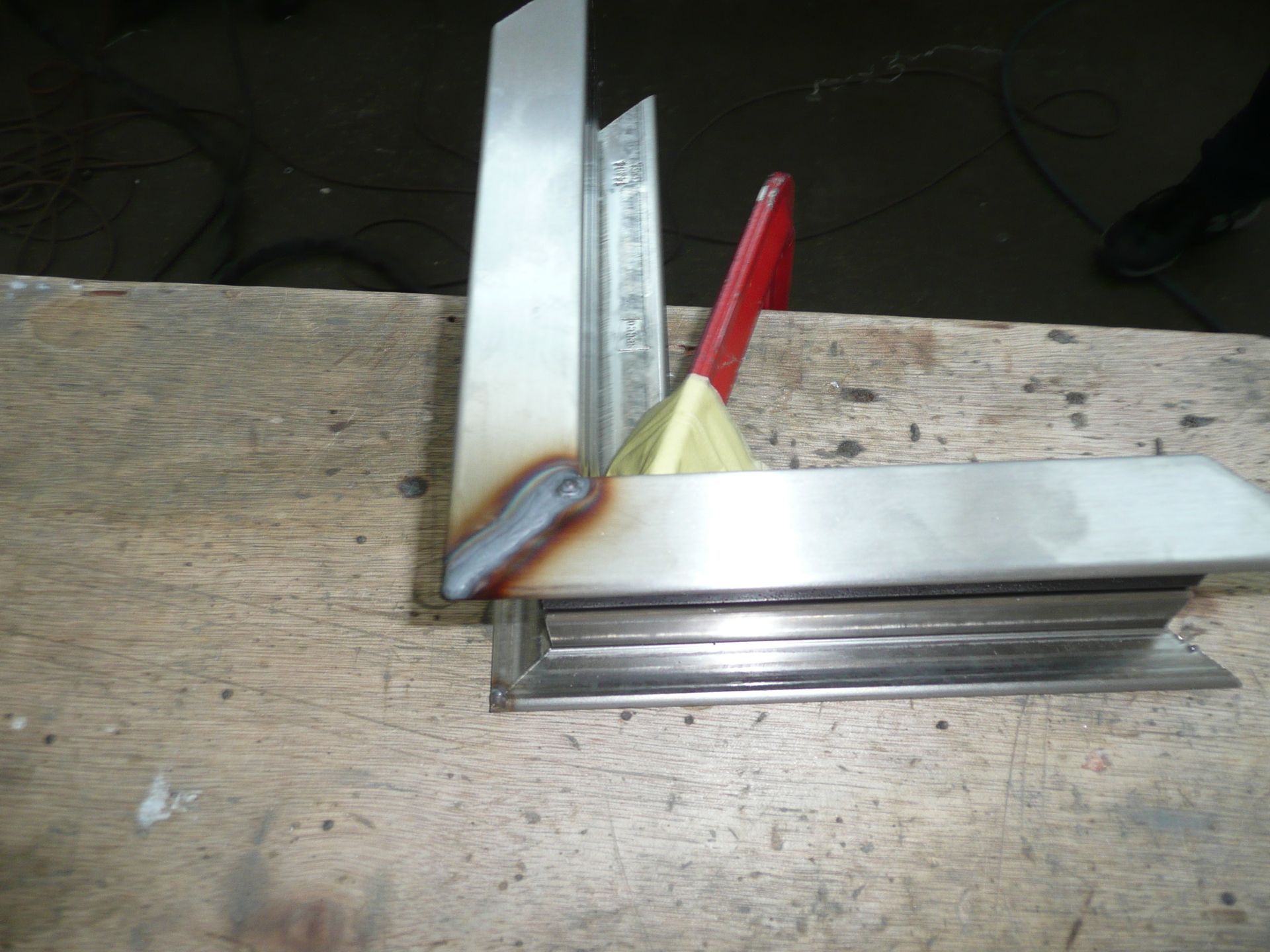

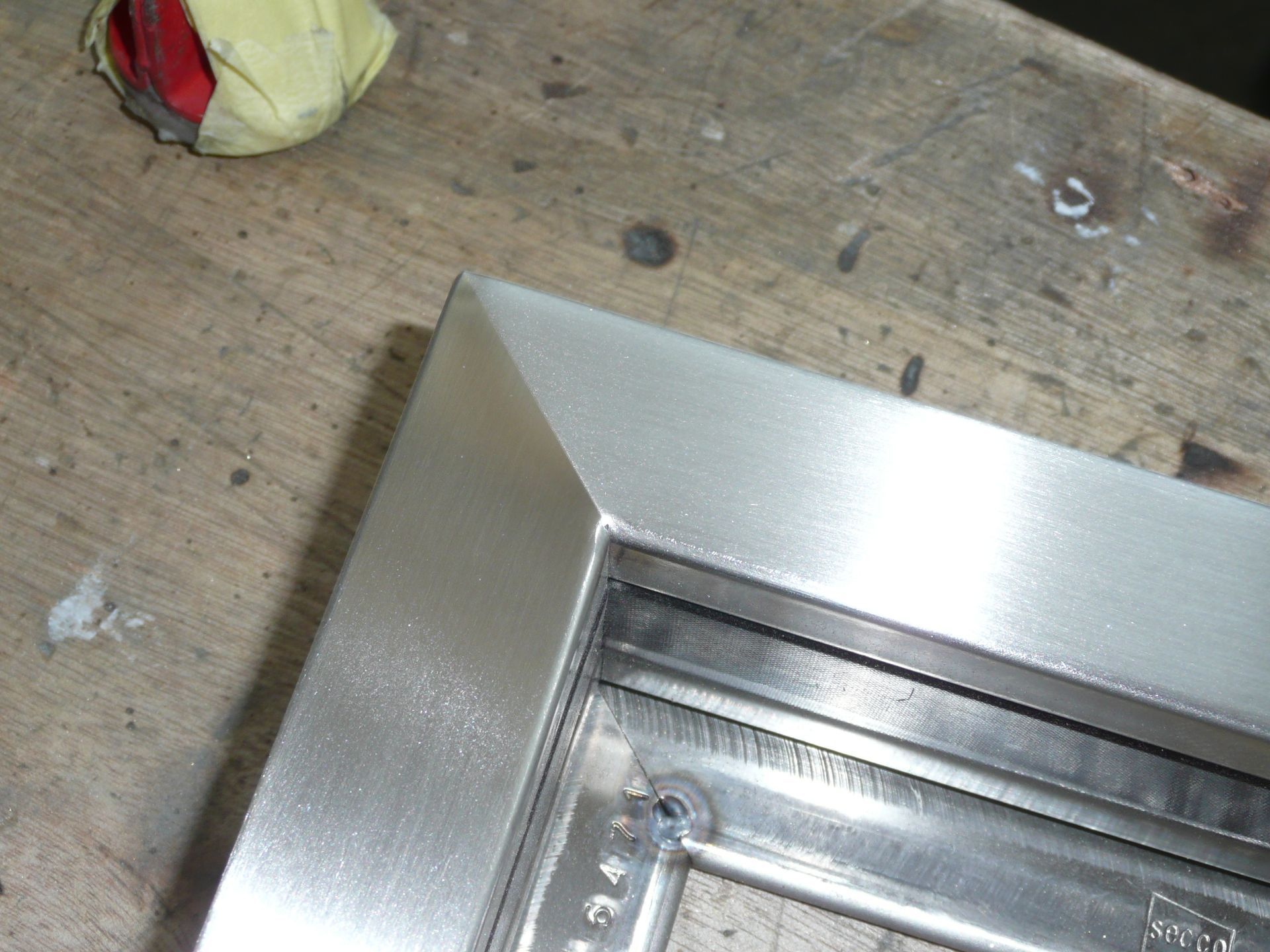

Brombal master craftsman welding and finishing a perfect mitered corner in high gloss scotch-brite finish. (He is the only one allowed to do this)

Brombal are in the process of expanding their factory and have recently installed new equipment to allow for a greater array of custom finishing to be done in-house.

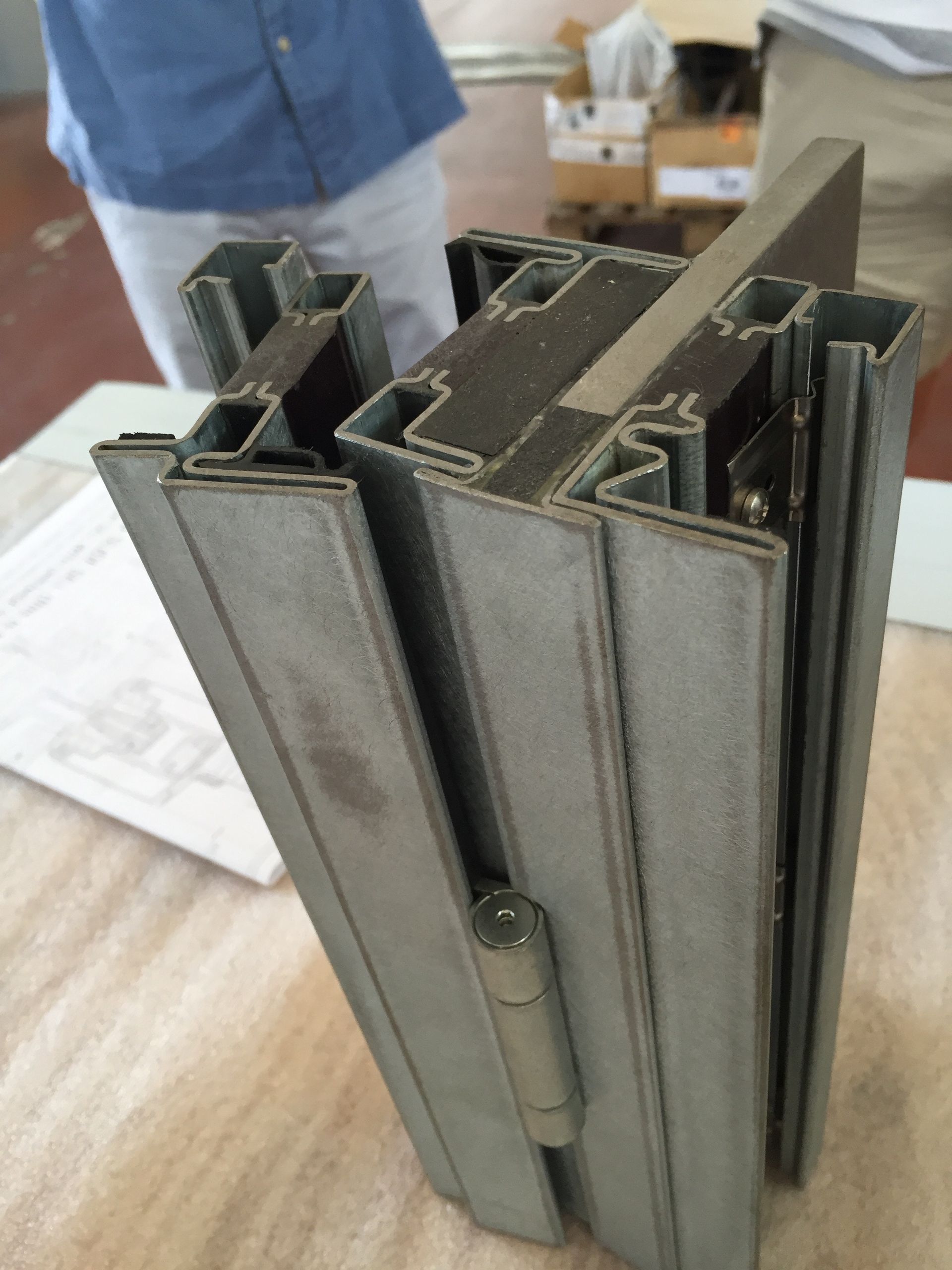

Direct set to operable window connection with stiffener.

Understanding the combining of different window profiles has been one of the most important elements of the design process for us in order to achieve the minimal frame dimensions we are trying to achieve aesthetically and to use the steel to its full potential.

Seeing the manufacturing and assembly of Brombal’s windows and talking with their staff in person has been an invaluable experience for our office. Understanding the potentials and limitations of a product allows us to streamline our process, make informed design decisions and be cognisant of what distinguishes them from their competitors. The trip to Italy didn’t hurt either and we are incredibly grateful to both Brad Wright at Alan Bradley Windows and Doors and the entire Brombal family for their generosity and hospitality in hosting and coordinating our incredible trip. Grazie mille a tutti!